Page 70 - 048

P. 70

52

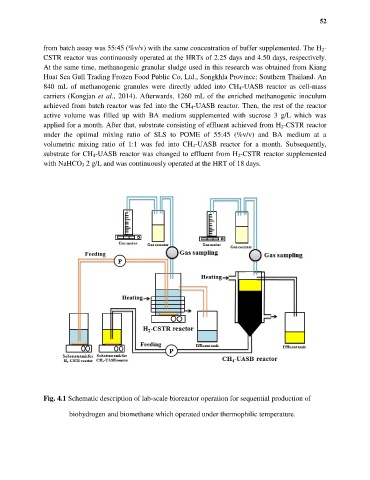

from batch assay was 55:45 (%v/v) with the same concentration of buffer supplemented. The H 2-

CSTR reactor was continuously operated at the HRTs of 2.25 days and 4.50 days, respectively.

At the same time, methanogenic granular sludge used in this research was obtained from Kiang

Huat Sea Gull Trading Frozen Food Public Co, Ltd., Songkhla Province; Southern Thailand. An

840 mL of methanogenic granules were directly added into CH 4-UASB reactor as cell-mass

carriers (Kongjan et al., 2014). Afterwards, 1260 mL of the enriched methanogenic inoculum

achieved from batch reactor was fed into the CH 4-UASB reactor. Then, the rest of the reactor

active volume was filled up with BA medium supplemented with sucrose 3 g/L which was

applied for a month. After that, substrate consisting of effluent achieved from H 2-CSTR reactor

under the optimal mixing ratio of SLS to POME of 55:45 (%v/v) and BA medium at a

volumetric mixing ratio of 1:1 was fed into CH 4-UASB reactor for a month. Subsequently,

substrate for CH 4-UASB reactor was changed to effluent from H 2-CSTR reactor supplemented

with NaHCO 3 2 g/L and was continuously operated at the HRT of 18 days.

Fig. 4.1 Schematic description of lab-scale bioreactor operation for sequential production of

biohydrogen and biomethane which operated under thermophilic temperature.